Snuffing the life out of the polythene devil

Following long periods of discussions, where there were disparities, the Government of Sri Lanka (GOSL) has shown some consistency in the build up to the ban on using disposable polythene.(The law will be effective from September). This decision will help minimize environmental issues caused by polythene usage.

It’s also fitting to note that the Central Environment Authority (CEA) has used all its tricks to promulgate the ban on polythene and the country’s law governing its usage.

Sri Lankan President Maithripala Sirisena, in his capacity as the Minister of Mahaweli Development and Environment, has proposed the implementing of a set of short, mediumand long term measures to minimize the use of polythene in Sri Lanka.

The measures recommended by the committee of intellectuals appointed to study the polythene issue received the approval of the Cabinet.

Short term measures proposed by President Sirisena to address the polythene issue:

- Prohibition of polythene use for decorations at all events.

- Implementation the prevailing regulations for the prohibition of, use, sale and production of polythene equals or less than 20 microns.

- Allowing the use of polythene less than 20 microns for essential activities only on the approval of Central Environmental Authority

- Prohibition of sale, importation and production of lunch sheets.

- Banning of sale, importation and production of containers, plates, cups and spoons.

- Prohibition of the sale of processed or cooked meals packed in polythene containers.

- Promotion of providing paper, cloth or reed bags or biologically degradable and environmental friendly plastics for customers when purchasing items.

- Prohibition of burning polythene and plastic in open places.

- Introduction and promotion of biologically degradable polythene and plastics.

- Imposing of 15% CESS during the importation of plastic raw material and related products and providing 5% out of that to the CEA to manage polythene and plastic waste.

Glass bottles must be made a renewable item

Hemantha Withanage

Centre for Environmental Justice Executive Director Hemantha Withanage revealed to the Dailymirror.lk that he was one of the committee members of the Eminent Panel appointed to study polythene use. “I was in fact affirmative on this regard and in a position to ban even plastic bottles which haven’t come under the new regulatory process. But I am glad that the law has been enforced after quite a few attempts in the past,” he said. Withanage proposed that glass bottles could be made renewable as the best alternative for the use of plastic bottles. He recommended the use of oil papers, wax paper bags and items made of sugarcane as the substitutes for polythene and plastic products.

“I should mention that many people who are in support of banning polythene and are waiting to adapt

themselves with the use of items made of materials harmless to nature. When this issue came under the spotlight in 1995, it was extremely difficult for the people to get used to it. But after more than 20 years, if anybody says that it’s still inconvenient to get used to it, that is actually ridiculous. If countries like Rwanda, Morocco, Kenya and most of the European countries can totally ban the use of polythene, why are we incapable of doing it? Let’s do it for the sake of all Sri Lankans,” he pointed out. He said that the use of polythene should have been nipped in the bud. Therefore, the people of Sri Lanka should make use of this opportunity to do away with the use of polythene and get used to other alternatives. He underscored that Sri Lanka is ranked 5th in the world with regard to disposing garbage in the sea. He also requested the general public to join hands to support this new program and strive to totally eliminate polythene use from Sri Lanka.

Tax and VAT concessions for biodegradable material and machinery

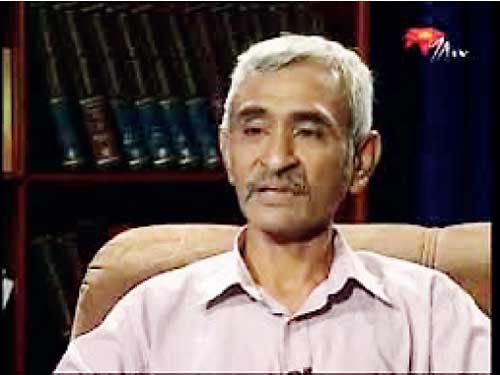

Ajith Weerasundara

Nevertheless, CEA Waste Management Director Ajith Weerasundara said that they would grant concessions regarding Taxes and VAT during the importation of biodegradable raw material and manufacturing machinery.

“We are in a firm position as to put this law into effect irrespective of any circumstances. Central Environment Authority (CEA) as a responsible branch aspires to conserve the environment. For that, we need the assistance and co-operation of the general public,” Weerasundara said. He mentioned that 10%-15% of polythene is inclusive in the total garbage collected daily and that one individual consumes 5kg of polythene per year which could exceed up to 7.2kg in the Western Province.

“We have discussed with the polythene manufacturing companies as to how they should face the music. We have recommended some of the products which are biodegradable. Some companies have supported our suggestions, but a few haven’t,” Weerasundara said.

Substitutes should be environmental friendly

Jagath Gunawardena

Senior Environment Lawyer Jagath Gunawardena when contacted, categorically stated that the problem wasn’t regarding the use of polythene, but the manner in which it was disposed of .

The lack of manageable procedures for the disposal of polythene has been the core issue during the past

“The lack of manageable procedures for the disposal of polythene has been the core issue during the past. I don’t say that the banning of polythene isn’t relevant. It’s absolutely essential and pertinent. The government should see that viable alternatives will be accommodated,” he opined. Gunawardena further emphasized that substitutes should be environmental friendly and come under the provision of Consumer Affairs Authority.

Govt. should carry out subsidiary measures

Sajeewa Chamikara

Environmentalist and Environmental Conservation Trust Director Sajeewa Chamikara told Dailymirror.lk that even though it was a bit late to implement the laws for the ban of polythene, the Government’s move was greatly commendable and applicable.

“I must say that the polythene issue has become a severe threat to Sri Lanka. Although, several implementations had been put into action, they weren’t as effective as they should have been.

Therefore, we should be thankful to this Government and the Central Environment Authority for their endeavours to implement the laws and the regulations to ban the use of polythene with effect from September 1,” Chamikara said.

He stressed that if we were to make this a reality, an apposite mechanism in the form of alternatives should be regulated to replace polythene. He pointed out that the government had regulated tax concessions for the importation and manufacturing of biodegradable raw material.

“The government should carry out subsidiary measures for the polythene manufacturers and the public before the law comes into effect to adapt themselves to the new alternatives.

When introducing alternative modes, the Government should ensure that their prices are affordable. The Government should take the pertinent steps to motivate the manufacturers of polythene. Otherwise, this will also be ineffective as it was evident for couple of times in the past,” he affirmed.

Chamikara further said that standards should be maintained and there should be legitimacy in enforcing the laws with respect to the ban on polythene, so as to not make it a

mere prohibition.

Unseen obstacles

In a brief interview with Dailymirror.lk , Sri Lanka Plastic Industry Association Chairman Sarath Wijesinghe, unearthed that the plastic industry in Sri Lanka would soon be in a tight spot due to the ban on polythene.

“The Government hasn’t provided enough time for the manufacturers to adjust themselves to alternative conditions. When there are more than thousand registered plastic factories at which there are more than 12,000 employees, the government hasn’t monitored its structures before banning polythene. It’s not fair,” Wijesinghe said.

He further said that more than 2 million lunch sheets are used daily in relative areas in Colombo. He went on to state that once the ban on polythene is effective, people will have to use items like boxes.

In order to wash them with water, it would require 5 litres of water per day.

He asked whether the Government could provide 5 litres of water per day only to Colombo? Therefore, they urged the Government to view this issue in a different perspective and take efficient action to see that the provisions proposed are fair.

Source – 11/08/2017, Daily mirror, See more at – http://www.dailymirror.lk/article/Snuffing-the-life-out-of-the-polythene-devil-134500.html

Saving us from plastic, one plate at a time

Disposable cutlery and containers are products that are a part of our day to day life. As a result of the ever-increasing number of food vendors in Colombo and the suburbs, plastic cups, plates and cutlery that are hardly used are seen tossed into bins regularly.

Dinnerware made from areca sheath

However there is a ban in place connected to disposable items. This means that the ordinary vendor and consumer must both take responsibility, a task that some are less inclined to embrace. A small group of entrepreneurs up North however are already taking action and demonstrating how to take responsibility by providing green solutions to the community. While many lament the inconvenience, this group isn’t only making good use of organic material, but also helping the environment, one plate at a time.

In Thirumurikandy, off the A9 highway, several kilometres before the Iranamadu junction,in Kilinochchi, an elderly gentleman opens the gates of a small enclosure to greet us. A small house sits in the middle of an expansive land with blossoming rows of tender coconut trees planted in between.  Areca sheaths hang from ropes tied between trees, drying out in the sun. As we enter the house several young women appear with welcoming smiles. No sooner than we can say hello, the young ladies spring into action, showing us what they are capable of with their new and exciting venture.

Areca sheaths hang from ropes tied between trees, drying out in the sun. As we enter the house several young women appear with welcoming smiles. No sooner than we can say hello, the young ladies spring into action, showing us what they are capable of with their new and exciting venture.

“The initiative was launched by our company this year in an effort to promote and embrace a greener lifestyle,” Gowri Ananthan of Kudhil products, facilitating this cottage industry said. “Our operational, research and development and training unit is situated in Ariviyal Nagar, Killinochi which is mainly focusing on providing job opportunities to war affected communities,” she said. The entrepreneurs hope to export the final products to US and Canada as well.

Manufacturing plates with areca sheath

“Apart from this, our company is engaged in importing and supplying machinery to extract banana fibre and to make plates and cups out of areca sheath. We also import and install coir pot making machinery, natural fibre weaving machinery and paper bag making machinery,” Gowri elaborated.

Brand new machines imported from India are installed in the verandah. Small piles of banana tree trunks and areca sheaths sit in the garden closer to the house. It takes a village to make organic disposable plates, we learn. Villagers collect locally grown areca sheaths and the native palmyrah sheaths which they use in the production of disposable dinnerware. Traditionally, areca leaves have been used to pack cooked rice and to preserve treacle made of “Fish Tail Palm”. Matured stems are used as a building material as well as for decoration of religious events. But in Kilinochchi, the ladies are quite busy collecting sheaths for a better cause. In addition to this, they also use the banana stem, purchased from villagers.

Once plantains are harvested the banana tree is disposed of, as it bears fruit only once. The stem of the banana plant has long been considered to be high in nutrition value, even though it is disposed of in most banana plantations. As a solution to the increasing issue of processing stem waste, entrepreneurs in South India began manufacturing bio-degradable dinnerware from organic waste such as the banana stem. Extracting good quality fibre from these stems is now a popular business enterprise especially with an increased need for reusable and environment friendly alternatives in Asia.

Purses made from banana fibre

Our operational, research and development and training unit is situated in Ariviyal Nagar, Killinochi which is mainly focusing on providing job opportunities to war affected communities

The manufacturing of plates involves a process of die cutting. A die is a specialized tool used in manufacturing industries to cut or shape material mostly using a press. Like moulds, dies are generally customized to the item they are used to create. The cutting process using a die is however a simple one. The upper die presses into the lower die assembly, with the dried sheath or leaf placed in between. The machine is operated by pressing a foot pedal. The heat regulator is set to maintain the main die temperature at about 150 Degrees Celsius. The die is heated by domestic energy which makes it ideal for a manufacturing set up in rural areas.

After a few seconds, the foot on the pedal is withdrawn and a cured leaf plate is produced. Finishing of the product is done by just trimming the edges of the manufactured plate. One of the most noteworthy attributes of this process we noted is that the manufacturing required no adhesive or chemical, making it completely safe for consumers. It’s a reliable, biodegradable and compostable alternative to petrochemical based plastic and polystyrene plates.

The plate machine

Still in its experimental and training phase, the employees are enthusiastically testing the possibility of making plates from lotus leaf as well. The revolutionary product is strong like its plastic rival and doen’t leak. But as we observed, the art of perfecting the skills of plate making is no easy task and requires efficiency of movement.

Still in its experimental and training phase, the employees are enthusiastically testing the possibility of making plates from lotus leaf as well

As the sheath is placed on the machine, it cuts and presses a portion of the leaf into a plate. The challenge for the operator is to try and save as much sheath left over as possible for the next plate. They also require the skill to know the precise moment when to lift the heated mold; when the plate is cured, but not burnt.

Meanwhile at another corner of the house, sat a young lady at a machine extracting fibre from banana sheaths. The extracted fibre after being dried are then woven into fabrics of beautiful shades. Another sat at a sewing machine, stitching together various pieces of woven mat and fabric. The final products they showed us included bags, purses and even pouches for phones. Successive Sri Lankan governments have always favoured bans, regardless of how prepared the country is to effectively implement it. The polythene and plastic ban which comes into effect from September 1, prevents the use of polythene lunch sheets, rigifoam boxes and shopping bags. While many are praising the move, another group are lamenting the inconvenience it will cause. The women and men of Kilinochchi taking up the challenge of providing a greener alternative, are indeed exemplary.

Source – 11/08/2017, DailyMirror, See more at -http://www.dailymirror.lk/article/Saving-us-from-plastic-one-plate-at-a-time-134501.html